What is Industry 4.0?

“Technology has revolutionized the way humans are living in the modern times, and now we are in industrial revolution 4.0” You might have read or heard the above-given line many times because technology has been revolutionizing our world for centuries and for every generation their current times were – “Modern Times”.

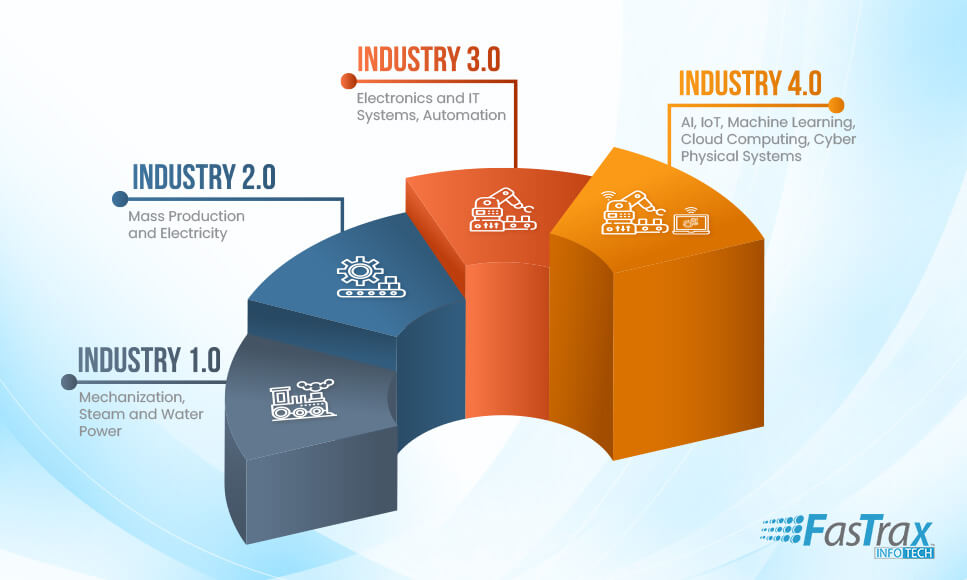

Back in 1784, when James Watt enhanced the steam engine with his improvements, it marked the beginning of Industrial Revolution 1.0. It changed many things for humankind. Those were the modern times then for the people of that era, but since we, as an existence, are evolving every second, we also kept innovating and inventing new technologies, and we went through the industrial revolutions 2.0 and 3.0.

This means that technology was, is, and will forever be revolutionizing humankind’s lives by impacting everyone right from the inventors to engineers, manufacturers, consumers, etc., and our modern times will soon become the “good old days” for the coming generation. This is the beauty of the human race as a whole; we never stop. We keep changing, advancing, and improving. And, this is the reason why, after, Industry 1.0,2.0, and 3.0, Industry Revolution 4.0 is in the process.

We are living in the middle of Industry Revolution 4.0. Many business giants have, in fact, embraced the advancements and used them to beat the competition. They know that if they don’t get into the grind, time will grind them out, which is a very positive and proactive approach for any company looking to stand the test of time.

Interested in making the most of industrial revolution 4.0?

Then read on to get detailed knowledge about revolution 4.0

What is Meant by Industrial Revolution 4.0?

Industrial Revolution 4.0 is the implementation of Artificial Intelligence, Machine Learning, Big Data Analytics, Internet of Things IoT, Genetic Engineering, quantum computing, and many more technologies to scale up and enhance the world’s industries, especially manufacturing.

Industrial Revolution 4.0 is a step forward to include more robots in the production with intelligent use of information sharing and interpreting technologies among the computer systems and machines.

Creating strong social networks for machines to communicate with each other, I.e., the Internet of things (IoT) and with people, I.e., the Internet of People (IoP) like manufacturers to create a cyber-physical production system (CPPS). This integrates the real world with the virtual one and empowers machines to collect live information and learn from it by analyzing it and then make decisions to perform tasks.

Deloitte’s below-given image explains the entire main events and happenings of all the industrial revolution 4.0 till now.

Has Industry 4.0 Arrived?

Yes, the industrial revolution 4.0 has been around for 8-9 years. It was first introduced in 2011 by the German government, and now with the covid19 pandemic transforming the entire world’s way of living, the revolution has speeded up because businesses have understood the need for production capabilities that can run with less human labor.

Let’s Discuss the Industry 4.0 Challenges and Opportunities

With every significant change comes a set of dedicated obstacles and chances, so let’s discuss that and clear out your doubts

Challenges with Industrial Revolution 4.0

-

1. Data Sensitivity:

This might be the most critical challenge because data in today’s world is even more important than money, and as technology rises, the risks of data and IP ownership, privacy, and management also grow with it. For example, if you have a third-party developing AI algorithm, they will ask data from you to train and test the developed algorithm. In such instances, you might hesitate to share your company’s data with a third party. And that’s common with many companies; anyone would be reluctant to share their critical data. Moreover, the data governance policies for internal use of data and cross-organizational data sharing are not strong enough.

-

2. Issues with Interoperability:

This challenge is something that the technology sector is trying to combat very efficiently. Interoperability is the ability of a machine to communicate and operate with other devices. There specific machines that only can work with sure others, so it becomes complicated to innovate and scale up because sometimes, to change one component, you might have to change the entire set just because the old components won’t work with the new ones.

-

3. Lack of Technical Skills:

Workforce skillset needs are also evolving with the technological developments. It would be best to have adept employees with the digital and technical knowledge to understand and operate the manufacturing process. Many people think that Industry revolution 4.0 will drive human laborers out of their jobs, but the thing is that it will only change the type of skillset required. Jobs will be there to implement, operate and monitor the entire manufacturing process successfully.

-

4. Data Growth Management:

When companies depend on AI, there will be more and more data collection happening, and your AI algorithm should be capable of comprehending all types of data and manage it.

-

5. Security:

Every factory is prone to have vulnerabilities, and hiding and improving those weak points is one hell of a task. Both physical and digital equipment are interconnected and have a type of interoperability in each company, and everyone wants to expand and innovate, which can be pretty risky sometimes. Several machines are interconnected in single or multiple networks in a manufacturing unit, and if any one of the systems becomes vulnerable to the attack, then the entire setup could be at risk. To ensure that a company is safe from digital attack, keeping a check on all levels’ weaknesses right from machine level to the enterprise system level.

Opportunities with Industrial Revolution 4.0

- Industrial Revolution 4.0 enables companies to collect a massive amount of data and analyze it very effectively, thus helping companies personalize their services to their consumers.

- Productivity can increase exponentially with the industrial revolution 4.0

- Collaborative robots (cobots), IoT-enabled quality improvement, and real-time monitoring will ensure that the manufactured products are of top-notch quality.

- The real-time economy now has real-time data collection for businesses who rely on real-time supply chains

- Increased sustainability and a safe working environment

- Smoother business operation is one of the perks that companies enjoy embracing industrial revolution 4.0 because of the improved technology.

How Industry 4.0 Enhances the Industry 3.0

It was a groundbreaking achievement when computers revolutionized the industries in industrial revolution 3.0. With the progress of time industry, 3.0 has been enhanced in many ways by industrial revolution 4.0.

The computers are now interconnected, and they even communicate and share information to make decisions with minimal human involvement based on the information they have. This is what industrial revolution 4.0 brought to the table that hugely improves industry 3.0. A combination of cyber-physical production systems, the IoT, and the Internet of systems has transformed industry 3.0 to 4.0.

Technologies That Made Industry Revolution 4.0 Happen

Numerous technologies play a pivotal role in industrial revolution 4.0.

-

1. Industry 4.0 and AI

It is probably the essential part. Artificial Intelligence, when first was founded in 1956, the entire community was blown away by the possibilities it brought. Some even thought that they would build robots or computers that could think like humans very soon. However, scientists are still trying to achieve that goal ultimately.

While trying to attain complete human intelligence for machines, innovators have now only reached a point where they can design robots and create programs that can run a few of the tasks that the human brain and body can perform. Nevertheless, this was also something significant that happened as it led people towards the industry revolution 4.0.

Artificial Intelligence has made Industry revolution 4.0 happen with enhancements that it brought to the table for industry 3.0.

You can see some of the areas where artificial intelligence has done wonders.

- Predictive Quality and Yield

- Predictive Maintenance

- Human-robot collaboration

- Generative design

- Market adaption/supply-chain

-

2. Industry 4.0 and IoT

Industry revolution 4.0 needs computers and other machines to communicate with each other by themselves and make decisions. The Internet of things makes communication happen between devices and the manufacturers or the managers, which is the backbone of industry revolution 4.0.

For example, if you have a production plant and if one of the machines stops functioning, how will you know about it? You might have to put human labor to log the downtime, which can be time-consuming and take time to communicate. A sensor or a Wi-Fi-enabled production line will help you track the production of each machine. In fact, you can let the devices communicate with each other, and that if there is a fault in one machine, the other in that network can adjust accordingly by themselves.

-

3. Industry 4.0 and Machine Learning

Machine learning made industrial revolution 4.0 happen because just setting up a network of AI-powered machines is not enough. It would be best to design algorithms that empower the entire network to learn from the available data and analyze patterns to draw references.

This motivated industries to give industrial revolution 4.0 as the entire machine structure could learn and adapt to the new challenges.

-

4. Role of Big Data Analytics in Industry 4.0

“It is estimated that only 1% of the data collected by companies is used; this percentage will exponentially increase with the 4.0 revolution”

With the rise of artificial intelligence-powered machines, data collection is all-time high; more data is utilized and analyzed. Companies have a large amount of unanalyzed data that is waiting to generate answers and opportunities for them. With big data analytics technology, you can take advantage of the large data pool to identify patterns.

By identifying patterns and feeding them to the programs, software, machines, you can help the entire structure of devices make decisions that will benefit your organizations in all sectors, be it production, customer service, marketing, sales, etc.

-

5. Industry 4.0 and Cloud Computing

Cloud computing supports industrial revolution 4.0 by empowering businesses to store and manage large chunks of data intelligently. The data stored can be accessed remotely. Information sharing becomes significantly more manageable, and as a result industrial 4.0 revolution thrives.

Industria 3.0 vs. 4.0

Industry 3.0, though supported by automatic machines, hugely depended on human fed data. A human controller was required to control and input commands for the device to perform. Industry 3.0 was devoid of machine learning, big data analytics, and IoT. As a result, machines are not self-evolving, hugely dependent on human interference, not automatically communicating with each other on a more profound and complex level, and do not collect and analyze data.

Whereas, in Industry 4.0, the machines will automatically analyze a colossal quantity of data and share it to perform specific tasks accordingly. Moreover, industry revolution 4.0 functions because of technologies like machine learning, IoT, Big Data analytics, and 3D Printing.

How Does FTx Infotech Contribute to Industry 4.0 Revolution?

FTx Infotech has always believed in forward-looking technologies because it understands the concept of keeping up with the “modern times”. You have to continuously experiment and evolve to keep yourself relevant to an ever-changing world.

At FTx Infotech, we have innovators who are industry experts; they know the importance of AI-powered automation software and are extremely capable of building one with solid algorithms.

FTx Infotech has already started working on projects that revolutionize retail and manufacturing industries by equipping them with software and apps that are entirely AI-driven and support Industry 4.0 intelligent factories’ entire structure. Be it warehouse software, mobile and web apps, big data analytics, enterprise cloud solutions, or anything, we are at the forefront of everything.

You can come to us with your requirements, and we can help you enhance your business according to Industry revolution 4.0.

FAQs

Moreover, the real-time data collection across all channels from suppliers to the end-users enables the businesses to analyze and improve their operations, design, and products. This ultimately improves productivity.

Industry 4.0 has changed the business models, which are more focused on providing a complete package to the customer, unlike the previous models in which the companies were majorly concerned about just manufacturing the product and selling it. Currently, companies do more than that -

Changing the “product only” mindset to the service mindset.

As industry 4.0 has given a boon of data sharing, the manufacturers and businesses have used the data to go a step further than just manufacturing a product. They have incorporated the Product Service System (PSS) that enables the manufacturers to create a complete experience for their customers, including the services after the product has been bought. For example, when you purchase iPhone, you are not just connected until the point of purchase; you are connected with Apple forever because after selling the phone, the app will start selling its services to you, some free and some chargeable. This creates an exclusive relationship with the customers, and with the data, they collect they personalize the relationship more smartly.

Customer Experience

Industry 4.0 creates value creation by enhancing the companies’ ability to be extra responsive and sensitive to the customers in ways beyond the traditional practices. Embedded systems, big data, augmented reality (AR), virtual reality (VR), and cloud computing are the technologies that can empower companies to connect with their consumers in unique and engaging ways. Manufacturers can understand that their customers better and accordingly treat them their concerns and needs. Real-time data collection and customer interactions can also help companies respond immediately or change their strategy immediately to fulfill the consumer’s exact demand. Moreover, many giant companies also offer on-demand customized products for customers.

Creating a Network

The foundation of industry revolution 4.0 is interoperability because communication between machines is essential. Also, horizontal and vertical integration of the value chain increases with manufacturer’s conventional roles integration. New value creation and creation of the sustainable self-evolving network is something that industry 4.0 needs, and to fulfill the needs, manufacturers have to make their business model more dynamic and well connected.

Smarter Products

Let’s retake the iPhone example, for example. Apple started producing a more intelligent product with exclusively unique functionality way before any other mobile brand even thought about it. That’s the reason apple become the brand it is. Always make your product smarter because your product will tell the customers about your company’s smartness and technological abilities eventually.

Manufacturers who offer products that have new technologies embedded in them like IoT, which makes the product look smarter, are beating their competition very quickly nowadays. Being innovative and more imaginative as far as technology is concerned will open new avenues for experimentation and creating fresh and advanced business models for manufacturers.

Industries should also evolve and figure out the ways to eliminate the issues like -

- Accuracy of data

- Slow Collection of data and sharing

- Errors

- Time-consuming processes

- Difficult to control the quality

- Inequality among highly skilled and moderately or less-skilled workers

- Cybersecurity risk.

- Core industries disruptions.

- Ethical issues

![10 Disruptive eCommerce & Design Trends for Stay-at-Home Economy [#5 Worth Paying Attention To]](https://www.ftxinfotech.com/wp-content/uploads/2020/06/eCommerce-Design-Trends-for-Stay-at-Home-Economy.jpg)

![How to Raise Fund for Your Mobile App Idea [The Proven Ways]](https://www.ftxinfotech.com/wp-content/uploads/2020/06/How-to-raise-funds-for-Mobile-App-1.jpg)

FasTrax InfotechQuick Connect

FasTrax InfotechQuick Connect Get In TouchLet’s talk more!

Get In TouchLet’s talk more! Call Us845-420-7961

Call Us845-420-7961